Construction Technology: 16 Building Technologies Driving the Future

Despite being a $12 trillion giant, the architecture, engineering, and construction (AEC) industry has historically been slow to embrace digital innovation with construction sites still looking similar to those of a century ago. However, the landscape is rapidly evolving.

To accommodate its growing demands, the construction industry has continually evolved, seeking new methods to enhance efficiency. For decades, technological advancements have propelled construction forward, benefiting both the industry and society at large. Innovative technologies have equipped the construction sector with more effective ways to complete projects.

In this blog, we’re going to help you digitally transform your construction company and get ahead of the competition by sharing the innovative tools and methods revolutionizing the construction industry.

From advancements in 3D printing to the latest in robotics and AI, these technologies are not just shaping new building techniques—they’re redefining the very framework of construction.

What Is Construction Technology?

Construction technology refers to the advanced tools, equipment, and methods used in the construction industry to enhance efficiency, safety, and sustainability. It includes a wide range of solutions such as 3D printing, drones, augmented reality, and automated machinery to support pre-construction activities and improve the production of quality building materials.

Rather than replacing skilled workers, these technologies focus on streamlining the most challenging and hazardous tasks in construction processes to improve project management and reduce costs.

These advanced technologies and innovative solutions assist in planning, designing, building, and managing construction projects more effectively, addressing challenges like labor shortages, safety concerns, and project delays.

How Has Construction and Building Technology Changed Over Time?

Construction and building technology have evolved significantly over time, driven by increasing demands for efficiency and safety. Early construction involved manual labor, but over the decades, technology like power tools and heavy-duty equipment emerged, improving productivity and safety.

The emergence of machine learning, artificial intelligence, and advanced software has further transformed the industry, allowing for more precise planning, increased productivity, and better resource management.

Technologies such as Building Information Modeling (BIM), prefabrication, wearable tech, and autonomous equipment are now integral, enhancing various aspects of construction from design to execution.

Moreover, there is a growing emphasis on sustainable building practices, using materials and methods that are environmentally friendly and energy efficient. Automation and robotics are also beginning to play a role in construction, promising further increases in efficiency and safety.

How Is Technology Changing the Construction Industry?

Technology is significantly transforming the construction industry by improving efficiency, safety, and productivity. Innovations like drones, augmented reality, and 3D printing enable precise site surveys, enhanced visualization, and rapid prototyping.

Additionally, software and data analytics are revolutionizing project management through real-time tracking and predictive analytics. These advancements are helping to overcome traditional challenges such as project delays and costs, labor shortages, and safety concerns.

The Challenges in Implementing Construction Technologies

Implementing construction technologies comes with several challenges, including high initial costs and the need for significant investment in new equipment and training. There’s also resistance to change within the industry, where traditional methods are deeply ingrained.

Additionally, compatibility issues between different technologies can complicate integration, and there are concerns about data security and privacy with the increased use of digital tools. There is also a significant skills gap in the workforce, as many workers lack the training to effectively use new technologies, which can slow adoption and limit the benefits.

Finally, regulatory challenges can arise, as current laws may not accommodate new technologies or the faster pace of construction they enable. Cybersecurity has become a critical concern as reliance on digital tools increases. Ensuring the security of sensitive data is paramount as more aspects of construction operations go digital.

The Benefits of Construction and Building Tech

Here are some examples of how construction and building technology can benefit your construction business:

Increases Safety

Construction technology can not only mitigate risks but also foster a culture of safety that spreads through all levels of a construction project, from planning through execution. Here’s how:

- Real-time Monitoring: Utilizing drones and sensors for continuous surveillance improves response times to potential safety hazards, ensuring constant oversight.

- Wearable Technology: Devices that monitor health indicators like carbon monoxide levels, motion, and temperature help prevent health-related incidents before they occur.

- Automated Machinery: Automating repetitive and high-risk tasks reduces the likelihood of accidents caused by human error, making sites safer for workers.

- Virtual Reality (VR): VR technology is used in safety training programs to simulate realistic scenarios. This allows workers to gain experience and practice handling dangerous situations in a controlled, risk-free environment.

- Robotic Layout Tools: These automate crucial yet repetitive layout tasks, reducing physical strain and exposure to injury-prone environments.

Enhances Efficiency and Productivity

Construction technology not only simplifies processes but also compresses construction schedules, directly impacting the bottom line by reducing costs and enhancing the quality of the final product. Here’s how:

- Building Information Modeling (BIM): BIM and automated construction equipment streamline complex processes, allowing for faster completion of projects with fewer errors. This leads to higher productivity rates and more efficient resource utilization.

- 3D Printing and Robotic Layout Printers: These technologies enhance efficiency by creating building components and printing digital models directly on-site. This precise approach reduces the need for rework, saving time and materials.

- Drones for Surveying and Mapping: Drones revolutionize site surveying by capturing aerial images and generating detailed maps. This enables more accurate and rapid data collection, facilitating better-informed site planning and design decisions.

- Artificial Intelligence (AI): AI is employed for project scheduling and resource management, significantly improving efficiency. By analyzing large volumes of data, AI algorithms help construction managers optimize schedules, effectively allocate resources, and minimize downtime, thus speeding up project completion.

- Prefabrication Techniques: The adoption of prefabrication involves manufacturing components off-site and transporting them to the construction site. This method not only reduces on-site labor but also minimizes waste and enhances quality control, speeding up the overall project timeline.

Better Quality

Construction technology collectively improves the overall quality of construction, ensuring that each project achieves a higher standard of excellence, sustainability, and functionality. Here’s how:

- Augmented Reality (AR): AR technology overlays digital instructions directly onto the physical job site, enabling workers to execute complex tasks with greater accuracy. This integration of virtual and real-world elements helps reduce errors and enhance the precision of construction work.

- Robotic Layout Tools: These tools print coordinated digital models directly onto construction surfaces with an accuracy of within 1/16 inch. This high degree of precision ensures that the work is not only of high quality but also adheres strictly to the specified designs, reducing the likelihood of costly mistakes.

- Precision Tools and Materials: The employment of advanced construction technologies involves the use of high-quality materials and precision tools. Coupled with sophisticated design software, these elements contribute to creating structures that are not only robust and durable but also aesthetically pleasing.

- Longevity and Aesthetics: The precise and informed application of technology in construction leads to buildings that are not only more structurally sound but also more visually appealing. This ensures that the structures are built to last and meet both functional and aesthetic standards.

Saves Time and Lowers Costs

Through construction technology, construction companies can achieve significant cost savings, improving their bottom line while remaining competitive in the industry. Here are some examples of how this can be achieved:

- Automation and Prefabrication: These techniques significantly expedite construction processes, leading to substantial time savings. This not only cuts down on labor costs but also reduces overall project expenditures.

- Advanced Project Planning and Management Tools: These tools aid in better scheduling and resource allocation, helping to minimize delays and prevent cost overruns. Efficient planning ensures projects stay on budget and meet deadlines.

- Optimizing Material Usage: Advanced analytics help in precisely calculating material needs, reducing waste and associated costs, thereby increasing the overall efficiency of construction projects.

- Energy-Efficient Design: Utilizing modeling software to create energy-efficient building designs not only reduces energy consumption but also lowers operating expenses over the building’s lifecycle.

- Remote Collaboration Tools: These tools decrease the need for travel, cutting down travel-related costs while enhancing communication among team members spread across different locations.

Improves Collaboration

Construction technology collectively fosters a more integrated approach to construction projects, leading to improved outcomes through enhanced collaboration. Here’s how:

- Cloud-Based Platforms: Digital tools such as cloud-based DAM software facilitate seamless collaboration among all stakeholders involved in a project, from architects and engineers to contractors and clients. These platforms allow for document sharing and access control, ensuring that everyone can work cohesively, regardless of their physical location.

- Project Management Software: This technology enables managers and team members to access real-time communications, updates, and a user-friendly dashboard whether they are in the field or out. This constant flow of information keeps all parties informed about the latest project developments.

- Automated Robotic Layout Tools: By printing all trades’ layouts directly from the coordinated model, these tools enhance collaboration and minimize cross-trade conflicts, streamlining the construction process.

- Building Information Modeling (BIM): BIM creates a comprehensive digital representation of the building process, improving coordination and communication among various disciplines. By allowing for early detection of potential conflicts, BIM helps to mitigate issues before they manifest on-site.

- Virtual Reality (VR) Walkthroughs: VR technology allows stakeholders to visualize and interact with project designs before construction begins, offering a powerful tool for enhancing understanding and communication between clients, designers, and builders.

Reduces Labor Shortages

The construction industry frequently struggles with labor shortages, a challenge worsened by an aging workforce and the retirement of experienced workers. Despite new workers joining the field, they often lack the experience and expertise of their predecessors, which can hinder the progress of construction projects.

However, technological advancements are proving instrumental in addressing these issues:

- Automation and Robotics: By automating routine and repetitive tasks, the industry can mitigate the effects of labor shortages. Robotics and other automated technologies also enhance productivity, allowing skilled workers to focus on more complex aspects of construction.

- Attracting New Talent: The integration of advanced technologies such as 3D printing, AI, and robotics into construction roles makes the field more appealing to a new generation of workers. These technologies offer a modern and engaging work environment, attracting individuals interested in tech-driven careers.

- Efficiency in Modular Construction: Innovations like 3D printing and AI tools are revolutionizing modular construction. These technologies automate tedious tasks, significantly reducing the need for a large workforce and allowing technicians to concentrate on specialized tasks.

Trends Driving New Construction Technology

Several trends are propelling advancements in construction technology. For example, the increasing need for sustainability is driving the adoption of green building techniques and materials.

Moreover, rapid urbanization demands faster and more efficient construction methods. Technological innovations such as AI, IoT, and robotics are becoming integral for enhancing productivity and safety on construction sites.

Additionally, digital tools like BIM are improving project visualization and collaboration among stakeholders, ensuring projects stay on schedule and within budget. These trends are critical in shaping the future of construction technology.

Examples of Construction Technology Impacting the Industry

Don’t fall behind and stay ahead by implementing innovative construction technology that your competitors refuse to. Let’s dive deeper and take a look at some construction technology examples and how they’re changing the construction industry for the better:

1. Virtual and Augmented Reality

Virtual and augmented reality (VR and AR) are transforming traditional construction methods, allowing for more accurate spatial planning and project execution, thereby enhancing efficiency and reducing costs in the ever-evolving construction industry.

As the industry anticipates a global growth of $8 trillion by 2030, the role of VR and AR is expected to become increasingly pivotal. These technologies have already demonstrated potential cost reductions of up to 90% in building costs since their implementation in 2022 and are extensively used for remote site inspections.

Furthermore, VR and AR are crucial in ensuring safety and facilitating better collaboration and communication among AEC personnel.

Training in the use of equipment and safety protocols is vital for any construction project. VR and AR offer safer, controlled environments for training scenarios, such as operating in confined spaces or at great heights.

VR simulators, long utilized in fields like the military and medicine, allow construction workers to practice complex tasks safely. This immersive training enables them to learn the correct procedures without the risks associated with physical job sites.

Augmented Reality enhances safety further by overlaying digital information onto the real world, allowing workers to interact with virtual tools, supplies, and equipment as if they were real. This integration helps workers familiarize themselves with their tools and environment safely before engaging in actual construction activities.

Additionally, these technologies also revolutionize client interactions and project planning. Immersive virtual walkthroughs allow your construction clients to experience realistic representations of future buildings before physical construction begins.

This capability is not only impressive in client presentations but also invaluable for making real-time design adjustments, which can lead to more efficient project execution and reduced delays.

2. Artificial Intelligence

The Construction Management Association of America (CMAA) has highlighted that Artificial Intelligence (AI) could potentially boost industry profits by 71% by the year 2035. Additionally, research indicates that leaders in construction data management are seven times more likely to implement AI and machine learning technologies.

AI is increasingly shaping the future of the construction industry by enhancing safety, streamlining workflows, and accelerating project completion.

As companies explore how best to integrate this complex technology, some larger firms are developing in-house AI programs to refine their decision-making processes and operational efficiency. Others are engaging AI consultants and third-party solution providers to evaluate their current practices and pinpoint areas ripe for AI or machine learning enhancement.

Moreover, AI and machine learning are proving invaluable on construction sites by automating tasks traditionally performed by humans, thereby freeing up personnel to focus on more critical aspects of their projects.

For example, AI systems can optimize site logistics by tracking how workers move around the site, which helps in organizing tools and materials more efficiently to minimize time wastage.

Additionally, AI can enhance monitoring efforts by using cameras to continuously record the project’s progress, comparing it against BIM models, 3D drawings, and schedules to ensure that construction stays on track.

AI’s capability extends to managing resources; predictive analytics can forecast potential delays or shortages by analyzing past project data. This foresight allows for better preparation and resource allocation, ensuring that projects adhere to timelines and budgets.

Additionally, AI’s real-time data analysis helps prevent the depletion of critical materials by predicting supply needs and scheduling timely replenishments.

3. 3D Printing

3D printing is set to revolutionize the construction industry by transforming how materials are sourced and utilized.

As construction technology, it facilitates the prefabrication of materials; components can be printed and then transported to the construction site, ready for immediate use. This process not only speeds up material acquisition but also simplifies logistics by eliminating several intermediate steps.

The technology enables on-site printing of materials, which significantly reduces waste and cuts down on transportation and storage costs.

Although 3D printing currently faces challenges in mass production due to the high cost of large-scale printers, it offers substantial benefits, including faster construction timelines, cost savings, and the ability to create complex, customized architectural designs.

Materials such as concrete and composite materials can be used in these printers, enhancing design flexibility and the structural integrity of buildings.

Moreover, 3D printing has already been identified as a major innovation in modern construction. Its potential continues to expand as the technology evolves from a novel concept to an emerging industry standard.

This advancement is particularly crucial in addressing issues like skilled labor shortages and enabling the construction of intricate designs and detailed architectural elements, such as facades, fixtures, and even furniture.

This is especially beneficial in remote locations or situations where supply chains are disrupted, as materials can be produced on-demand, reducing wait times from months to just hours or days.

Looking forward, the maturation of 3D printing technologies is expected to continue, driving improvements in quality control and opening up new possibilities for advanced designs.

This technology not only supports rapid prototyping of building components, making production more efficient and precise but also promotes sustainability by minimizing construction waste and optimizing material use.

These capabilities unlock new design possibilities that were previously difficult or impossible to achieve with traditional construction methods.

4. Building Information Modeling (BIM) Software

Building Information Modeling (BIM) software significantly enhances construction project planning and execution. It facilitates the creation of 3D models that integrate all project data in one place, fostering better collaboration among stakeholders by replacing disparate 2D drawings. This integration boosts efficiency and communication throughout the project lifecycle.

Globally, BIM adoption is being accelerated by mandatory regulations in countries like the United Kingdom and is increasingly embraced in places like India, Hong Kong, France, South Korea, Germany, and Italy.

Moreover, BIM’s utility spans beyond design into the field, where it ensures data accuracy and reduces the need for rework. It enhances the visibility of project details among teams, which facilitates more precise planning and execution. Experts predict that BIM will increasingly focus on data-driven management, leveraging AI for smarter decision-making and operational efficiencies.

Beyond project execution, BIM supports post-construction phases by aiding in maintenance scheduling, which helps keep structures up to code and optimizes upkeep costs. It also serves as a base for virtual reality applications in construction, enabling virtual simulations that improve planning and stakeholder engagement.

The evolution of BIM from a design tool to an all-encompassing project management solution is transforming the construction industry.

With ongoing advancements and broader regulatory adoption, its impact on improving project efficiency, safety, and cost management continues to grow, highlighting its critical role in modern construction practices.

5. Automated Data Collection and Predictive Analytics

Data collection apps are transforming how construction companies gather information from job sites—quickly, accurately, and efficiently.

These apps not only integrate seamlessly into existing processes with minimal upfront investment but also offer significant benefits, such as:

- Time Savings and Accuracy: Users often save over 20 hours per week in field and administrative tasks, and see a 50% reduction in data entry errors.

- Enhanced Workflows: Automation of data collection workflows can trigger subsequent necessary actions, streamlining the completion of tasks with all required approvals and data.

- Safety Compliance: These apps support crucial safety measures, from equipment inspections to incident reports.

- Instant Reporting: Apps facilitate rapid production of reports, from daily job summaries to client deliverables, customizable to specific business needs.

Furthermore, predictive analytics and machine learning are becoming staples in the construction tech stack, allowing firms to use past and present data to forecast outcomes, enhance decision-making, and optimize workflows.

These technologies not only mitigate risks and enhance efficiency but also allow construction professionals to concentrate on more strategic, value-adding activities.

6. Drones

Drones have become a cornerstone technology in the construction industry, offering significant advantages for surveying and inspecting sites. They enable rapid and precise site surveys, outperforming traditional ground crews in both speed and accuracy, and are more cost-effective than manned aerial imaging.

Equipped with high-resolution cameras, drones generate interactive 3D or topographical maps and models, as well as perform volume measurements.

One of the key benefits of drones is their ability to access and inspect hard-to-reach areas such as bridges and the exteriors of tall buildings safely. They also play a crucial role in monitoring ongoing progress at construction sites, providing a bird’s eye view that helps track how projects and personnel are progressing.

Additionally, drones not only enhance the safety of inspections by keeping workers off dangerous heights but also bring efficiency to data collection across expansive or difficult terrain.

With capabilities like light detection and ranging (LiDAR), they can gather detailed scan data, offering a comprehensive overview of a site’s condition and topography.

By integrating drones into their operations, construction professionals can achieve a more informed, efficient, and safe workflow, transforming the way construction sites are managed and monitored.

7. Robotics

Robotics in construction is revolutionizing the way tasks like bricklaying, demolition, and excavation are conducted. These robotic tools not only reduce the necessity for manual labor, thus decreasing potential injuries and worker fatigue but also boost efficiency and enhance safety on-site.

By automating routine and physically demanding tasks, robots allow construction workers to concentrate on more intricate aspects of projects.

The integration of robotics in the construction industry faces challenges such as high initial costs and a skills gap within the workforce. Many robotic applications are still in the pilot phase as the industry explores their most effective uses and the significant impacts they can have on projects.

To address these challenges, construction firms are encouraged to begin with more established technologies, like drones and offsite prefabrication, and to invest in training and partnerships with technology providers.

Such collaborations are essential for tailoring AI and robotics solutions to meet specific construction needs and for learning from industry pioneers who have successfully integrated these technologies.

The adoption of robotics in construction promises substantial benefits in productivity, efficiency, and safety, leading to optimized workflow, improved resource management, and accelerated project delivery.

Moreover, robotics reduce physical strain on workers and minimize their exposure to hazardous conditions, thus contributing to a safer working environment.

While robots perform repetitive tasks effectively, they still require human oversight to ensure accuracy and address any issues promptly, blending automated efficiency with professional expertise. This synergy between humans and machines enhances overall project execution and safety.

8. Project Management Software

Incorporating project management software into construction operations not only streamlines various project management tasks but also provides a strategic advantage in managing complex construction projects more effectively.

This type of software provides a robust framework for project planning, execution, and monitoring, ensuring that construction projects are delivered on time, within budget, and according to specifications.

To begin, project management software allows for detailed planning and scheduling of all project activities. Managers can allocate resources more effectively, plan tasks in a logical sequence, and set realistic timelines. This helps in minimizing delays and ensuring the project stays on track.

Moreover, these tools facilitate better communication between all parties involved in a construction project, from contractors and suppliers to clients and stakeholders.

Centralized communication features within the software ensure that everyone has access to the latest updates, changes, and documentation, reducing misunderstandings and conflicts.

Additionally, project management software helps in tracking project costs and budgets in real time. It allows project managers to input costs, track expenses, and compare them against the allocated budget, thus providing a clear picture of the financial health of the project at any point in time.

Lastly, project management tools help in maintaining the quality of the construction project by monitoring compliance with industry standards and regulations. Regular reporting and auditing features within the software ensure that all aspects of the project meet the required quality benchmarks.

9. Wearables

Wearables in the construction industry go beyond traditional personal protective equipment (PPE) like hard hats, gloves, and work boots, enhancing safety and productivity significantly.

Modern wearables, equipped with advanced technology, include items like XOEye Smart Glasses, Spot-r Wearable Sensors, and Redpoint Positioning Safety Vest Sensors, which are designed to monitor various aspects of a worker’s environment and health.

These devices can increase productivity by 8.5% and workplace satisfaction by 3.5% by integrating biometrics, environmental sensors, GPS tracking, and voltage detection. OSHA also recognizes that these devices could not only help reduce insurance premiums but also enhance employee health and safety.

This technology not only tracks a worker’s location but also improves safety management through features like geofencing, which alerts workers with audio and visual signals when they approach restricted or hazardous areas.

Smart clothing, or e-textiles, further extends the capabilities of wearables in construction. These garments are designed to monitor vital signs such as heart rate, respiration rate, and skin temperature, and also detect abnormal patterns in movement and posture.

This real-time data helps ensure that workers are physically fit for their tasks, promoting safety by preventing accidents related to health issues or fatigue.

Overall, the integration of wearables into the construction sector marks a significant shift towards a safer and more efficient working environment, leveraging technology to protect and enhance the well-being of workers.

10. Digital Twins

Digital twins are transforming the AEC industry by offering a revolutionary approach to operational management through simulation and real-time data analytics.

As a cutting-edge technology, digital twins create intelligent, multidimensional models of buildings, enabling the simulation, prediction, and enhancement of building operations based on actual conditions and user behaviors.

A digital twin acts as a dynamic digital replica of a physical structure, encapsulating everything from its assets and systems to the workflows and people involved. This technology allows construction professionals to build out a comprehensive digital counterpart from the outset, providing critical insights for optimizing future operations.

By analyzing the digital twin, teams can identify opportunities to enhance efficiency, develop robust safety measures, mitigate risks, and elevate overall quality.

Moreover, digital twins integrate seamlessly with Building Information Modeling (BIM) systems, serving as a continuous digital thread that connects directly to the physical structure. This integration is crucial because approximately 80% of a building’s lifetime value is realized during its operational phase.

The insights gathered from digital twins enable owners to maintain their facilities more effectively, streamline operations, and refine capital planning strategies.

Digital twins also prove invaluable in tracking and achieving construction Key Performance Indicators (KPIs) and sustainability goals, as well as in assessing equipment performance and planning for future needs based on real-world data.

The relevance of digital twins has become particularly pronounced in the context of remote work, social distancing, and travel restrictions. They provide essential information about properties remotely, making it unnecessary to visit sites physically.

This capability ensures that critical decision-making can continue unimpeded, regardless of physical location constraints.

11. Sustainable Technology

Sustainable technologies are transforming the construction industry by making buildings more energy-efficient and environmentally friendly. Integrating smart technologies and sustainable materials are at the forefront of this revolution.

Here are some examples of what sustainable technology in construction looks like:

- Energy-Efficient HVAC Systems: These systems are crucial to improving air quality and reducing energy consumption. By efficiently regulating temperature and airflow, they ensure a healthier indoor environment while lowering energy costs.

- Integrated Smart Controls: Smart controls streamline the management of various building functions, including lighting, security, and more. This centralization not only enhances the functionality of buildings but also contributes to significant energy savings.

- Use of Sustainable Materials: Materials like recycled steel and bamboo are becoming increasingly popular in construction due to their low environmental impact and high durability. These materials help preserve natural resources and reduce the carbon footprint of building projects.

Together, these advancements not only lead to smarter buildings that prioritize occupant comfort and safety but also promote sustainability in construction practices, paving the way for a more eco-friendly future in building design and construction.

12. Blockchain Technology

Blockchain technology is rapidly becoming a transformative force in the AEC industry.

Initially introduced to the sector less than a decade ago, blockchain serves as a digital ledger, composed of linked data “blocks” that record every transaction and completed milestone in a project. This setup not only enhances cost management and procurement strategies but also introduces a high level of accuracy and security.

As we look ahead, the decentralized nature of blockchain makes it a robust, adaptable tool for projects of any size. Its ability to automatically update and balance makes it comparable to a chain where each link represents a distinct transaction, ensuring data integrity and reducing discrepancies.

Blockchain’s potential goes beyond just transaction management; it includes smart contracts, which are self-executing agreements embedded with the terms of the contract directly into the code.

These contracts automate processes, eliminating the need for middlemen and speeding up operations. This aspect is particularly beneficial in construction, where numerous transactions and agreements occur, often requiring significant time and verification.

Moreover, the security features of blockchain are exceptional, thanks to its decentralized structure and the use of cryptographic algorithms that protect data from tampering and fraud.

The consensus mechanism employed in blockchain also ensures that all participants agree on the validity of transactions, further enhancing the trust and reliability of data.

Blockchain’s transparency, security, and efficiency are setting the stage for profound changes across various industries, including finance, healthcare, and supply chains.

As this technology continues to evolve, its capacity to revolutionize data maintenance and transaction processes appears boundless, promising significant advancements in how industries operate.

13. Prefabrication and Modular Construction

Prefabrication is transforming the construction industry by enabling buildings to be assembled quickly and more efficiently. This method involves creating essential building components off-site, which are then transported and assembled at the construction site.

Over the years, demand for rapid construction has encouraged the adoption of prefabrication alongside other methods like modular construction.

Moreover, prefabrication has evolved significantly with the rise of 3D printing technologies.

Modular construction is another form of off-site construction. It involves constructing entire sections of a building—like rooms complete with fixtures—in a factory setting. This method is particularly useful for large-scale projects such as apartment complexes and hotels, where identical units can be produced en masse and then assembled on-site.

It’s important to distinguish between prefabrication, modular construction, and off-site construction, although these terms are often used interchangeably.

Modular construction specifically refers to the creation of pre-engineered modules that can form various configurations of a building. Prefabrication generally involves producing various building elements separately at a factory.

Off-site construction encompasses both techniques, highlighting the shift of construction activities from the site to a controlled factory environment. This not only enhances safety and efficiency but also significantly cuts down construction time.

Overall, these methods signify a shift towards more controlled, efficient, and safer construction practices, meeting the modern demands for speed and precision in building projects.

14. Sensor Data

Sensor data is becoming increasingly critical in managing various aspects of construction projects, including manpower, job sites, and equipment. Effective monitoring enhances project planning, streamlines operations, and ensures adherence to safety and regulatory standards.

Thanks to advancements in construction sensors and IoT technology, overseeing the numerous components of construction projects has become more straightforward.

The market offers a range of solutions that allow for comprehensive monitoring of site conditions, tracking of materials throughout the supply chain, enhancement of worker safety, and improved facility management.

Progressive companies are leveraging sensor data not only for monitoring but also for predictive purposes. For example, some firms use this data to anticipate potential product failures.

This predictive capability allows for proactive maintenance scheduling, which can reduce the frequency of on-site visits and thus minimize traffic, contributing to a smaller environmental footprint. This strategic approach not only boosts efficiency but also supports sustainability initiatives within the construction industry.

15. 4D Simulation

4D simulation is increasingly recognized as a critical tool for optimizing construction processes and merging time management with 3D Building Information Modeling (BIM) to enhance project efficiency and reduce costs.

This approach, which builds on the widespread adoption of 3D BIM, integrates time-related information to facilitate detailed planning and scheduling. Such information can include installation periods, lead times, drying periods, and potential scheduling adjustments.

The primary goal of 4D BIM is to improve project management by aligning detailed time planning with overall project optimization and client satisfaction.

This methodology not only keeps projects on track across all phases—from planning and design through to construction—but also significantly enhances the precision of data collection for future use.

By implementing 4D BIM, construction firms can streamline operations, improve output, and optimize resource allocation. Today, leading construction firms consider 4D BIM a fundamental component of their service offerings.

Adopting this technology positions your construction company at the forefront of the industry, providing you with a competitive edge by showcasing your capability to handle complex scheduling and project management challenges efficiently.

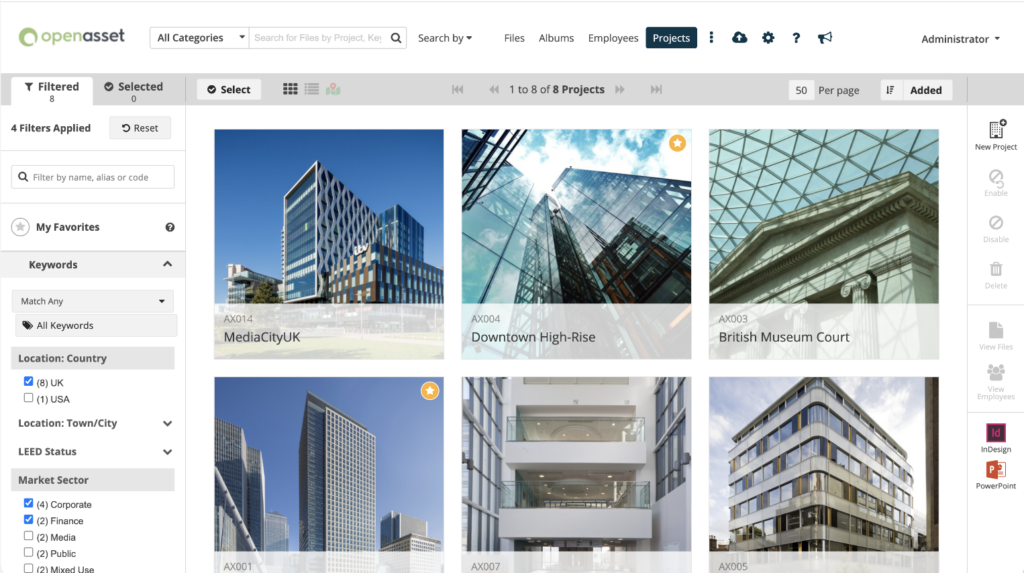

16. DAM software

Digital Asset Management (DAM) for construction, like OpenAsset, plays a crucial role in the AEC industry by optimizing the management and use of digital assets. This technology solution is specifically designed to streamline workflows, enhance proposal creation, and efficiently store, find, use, and share digital assets within your AEC firm.

DAM software acts as a central repository for all digital content, making it easier for teams to find and use the right assets at the right time. It supports powerful tagging and categorization features, which means assets can be quickly located through search functionality, saving time and reducing duplication of effort.

Moreover, digital asset management designed for AEC firms will integrate seamlessly into the existing technology stacks of AEC firms, automating the organization and management of digital assets such as photos, graphics, and project documents.

This automation significantly reduces the time spent searching for files, enabling team members to focus more on project delivery and less on administrative tasks.

Additionally, crafting winning proposals is key to winning more business. DAM software supports this by providing easy access to high-quality images and documents with consistent branding that showcases a firm’s previous projects and capabilities.

This not only improves the aesthetic appeal of proposals but also helps communicate the firm’s expertise and success in a visually engaging way in no time.

| Hand-picked related content: Want to inspire and convert to grow your construction business? Read our blog which provides examples of the 25 Best Construction Websites to influence your construction website efforts. |

With a DAM solution like OpenAsset, your AEC firm can achieve more organized and accessible digital libraries, enhanced collaboration among team members, and improved efficiency in your marketing plans and project management efforts. This ultimately contributes to better project outcomes and a stronger competitive edge in the marketplace.

Building Construction Technology Investment

Adopting modern technology in any business should be considered an investment rather than an expense.

According to McKinsey & Company, between 2020 and 2022, investment in AEC technology soared to approximately $50 billion, marking an 85% increase over the previous three years. At the same time, the number of industry deals rose by 30%, reaching a total of 1,229 transactions.

The cost of implementing construction technology can vary widely depending on the specific technologies and scale of adoption. Initial expenses can be high due to the need to purchase advanced equipment, software, and training employees. Ongoing costs include maintenance, updates, and potentially higher energy or data usage.

However, these investments can lead to long-term savings through improved efficiency, reduced waste, and fewer costly errors, as discussed in this article. Each company must carefully consider its specific needs and potential return on investment (ROI) when adopting new technologies.

During the decision-making process, it’s crucial to weigh the advantages and disadvantages of each option thoroughly. If investing in new technology seems financially daunting, government incentives and legal adjustments can facilitate digital transformation in construction.

Moreover, many construction management software providers offer free trials or demos, allowing companies to explore options without initial costs. Some providers also support software implementation, helping you save time and maintain team productivity.

How to Select the Right Construction Tech

Selecting the right technology for your construction company involves a systematic approach to ensure the tech aligns with your specific needs and enhances operational efficiency.

By methodically addressing the following areas, you can make informed decisions that align with both your immediate needs and long-term business goals, ensuring that investments in technology drive value and competitiveness in the construction industry.

Here are key steps and considerations to guide your decision-making process:

1. Identify Specific Needs

Begin by pinpointing a specific problem or inefficiency within your operations that technology could solve. This targeted approach helps prevent the unnecessary adoption of technology that doesn’t serve a direct purpose for your business.

If your company specializes in interior renovations, for instance, investing in drones might not provide the best return on investment compared to other technologies more aligned with your workflows.

2. Conduct Thorough Research

Invest time in researching potential technological solutions. This includes reading product reviews, checking user testimonials, and understanding the features and limitations of each option.

Consider factors such as ease of use, cost, integration capabilities with your current systems, customer support, scalability, mobility of the solution for fieldwork, and data security. This step is crucial in narrowing down the choices to those that best fit your company’s needs and budget.

3. Trial and Evaluation

Before making a final decision, it’s advisable to test the technology. Many vendors offer trial periods, which allow you to see how the tech integrates with your existing operations and whether it effectively addresses the problem it was intended to solve. This period is vital for assessing the practicality of the technology and its adoption by your team.

4. Ensure Team Buy-In

The successful implementation of new technology also depends on the buy-in from both management and the staff who will use it. Engage with your team early in the decision-making process to gather their insights and preferences. This not only helps in choosing the right tool but also facilitates smoother integration and acceptance once the technology is deployed.

5. Evaluate Success and Scalability

After implementing the technology, continuously assess its impact on solving the identified problem and improving your business processes. Successful initial integration can pave the way for further technological adoption, which can cumulatively enhance productivity and efficiency across your operations.

The Future of Construction Technology

The future of construction technology promises significant advancements that will continue to reshape the industry.

One of the key trends on the horizon is the increased integration of Digital Asset Management (DAM) software. This technology is not just about storing and organizing digital assets; it’s about leveraging these assets to streamline workflows, improve proposal accuracy, and enhance overall project management.

OpenAsset, as a DAM specifically designed for the AEC sector, enables construction businesses to efficiently manage a growing library of digital content, from project photography to project documents. This centralization of resources facilitates quick access to necessary assets, helping marketing teams, bid preparation, and project execution.

| Hand-picked related content: Want to improve the marketing efforts at your construction firm? Read our ultimate guide on Digital Marketing for Construction Companies or get inspired by post ideas you can find in our Construction Social Media Marketing blog. |

Ultimately, OpenAsset helps firms avoid redundancies and speeds up the retrieval process, thereby saving time and reducing costs.

Furthermore, the integration of this software into daily operations ensures that every team member has access to the most up-to-date and relevant documents, improving decision-making and enhancing collaboration across projects.

As the construction industry continues to evolve, the role of technologies listed in this article, like OpenAssset, will become increasingly crucial. These tools contribute to the broader goals of increasing productivity and driving innovation in construction practices.

With such technologies, firms are better equipped to meet the demands of complex projects and dynamic market conditions, securing a competitive edge in the rapidly changing construction industry.

Ready to embrace digital innovation and get ahead of your competitors?

The post Construction Technology: 16 Building Technologies Driving the Future appeared first on OpenAsset.